A RECENT PARK, AT THE HEART OF TECHNOLOGY

Every year, we invest between 10 and 12% of our turnover in the renewal of our machinery. This allows us to always have the latest generation equipment and remain at the forefront of technological advances.

OUR KNOW-HOW

In 3 extrusion workshops, spread across 2 sites:

26

machines including:

5

co-extrusion blowers

1

test & research blower

We use a powerful compressed air processing unit that filters the air from our vial manufacturing process.

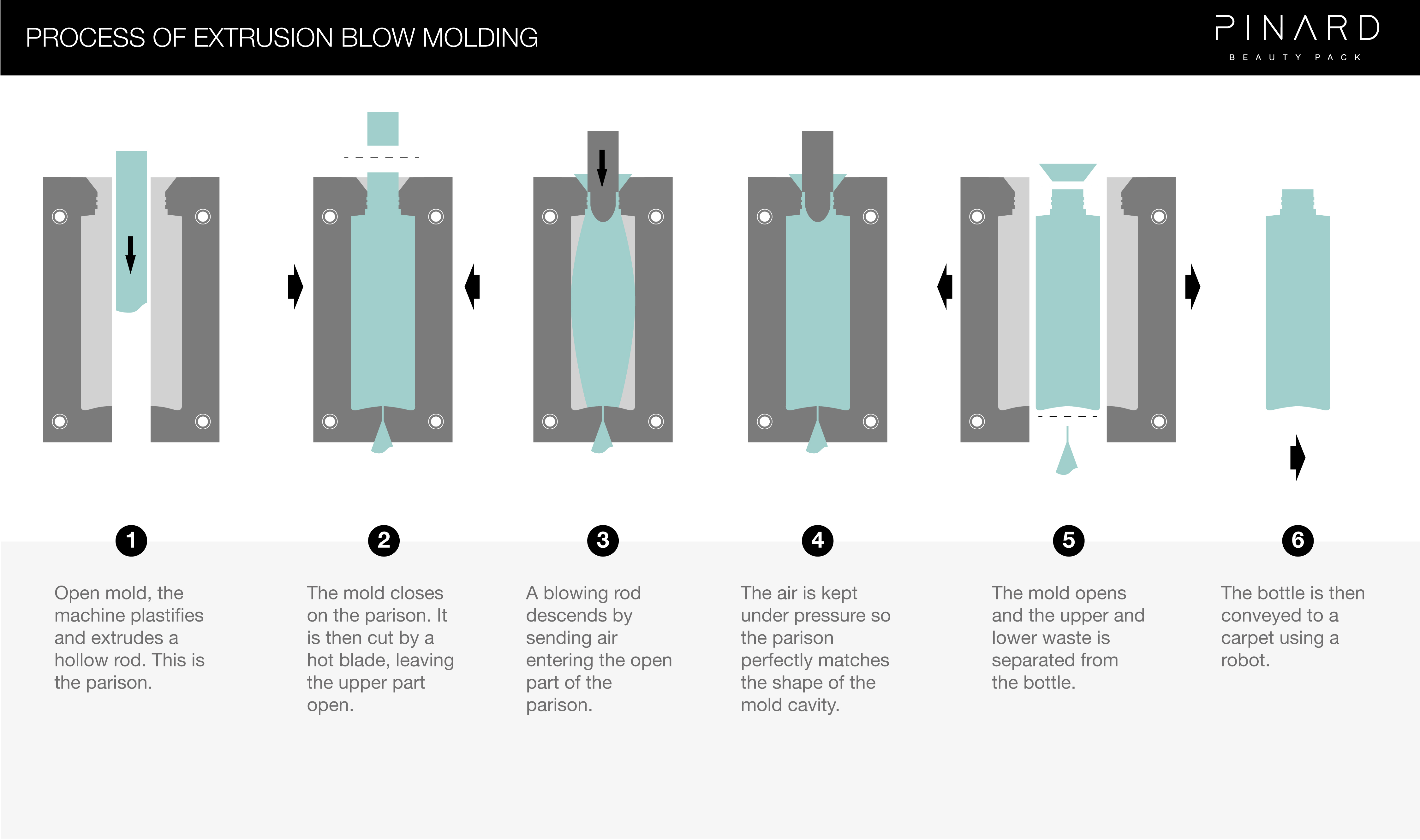

Extrusion and coextrusion blow molding

This process consists of combining the extrusion technique with the blowing technique. An extruder plastifies the material, then, with the aid of the extrusion head, the material is transformed into a hollow tube calibrated by a die and a punch. The parison is then trapped in a mold and a blowing rod is introduced by blowing compressed air to inflate the parison so the plastic will marry the inner walls of the mold.

In 3 extrusion workshops, spread across 2 sites:

26

machines including:

5

co-extrusion blowers

1

test & research blower

We use a powerful compressed air processing unit that filters the air from our vial manufacturing process.

In the 2 blow molding workshops:

19

Bi-oriented hot cycle machines

1 to 10 indentations

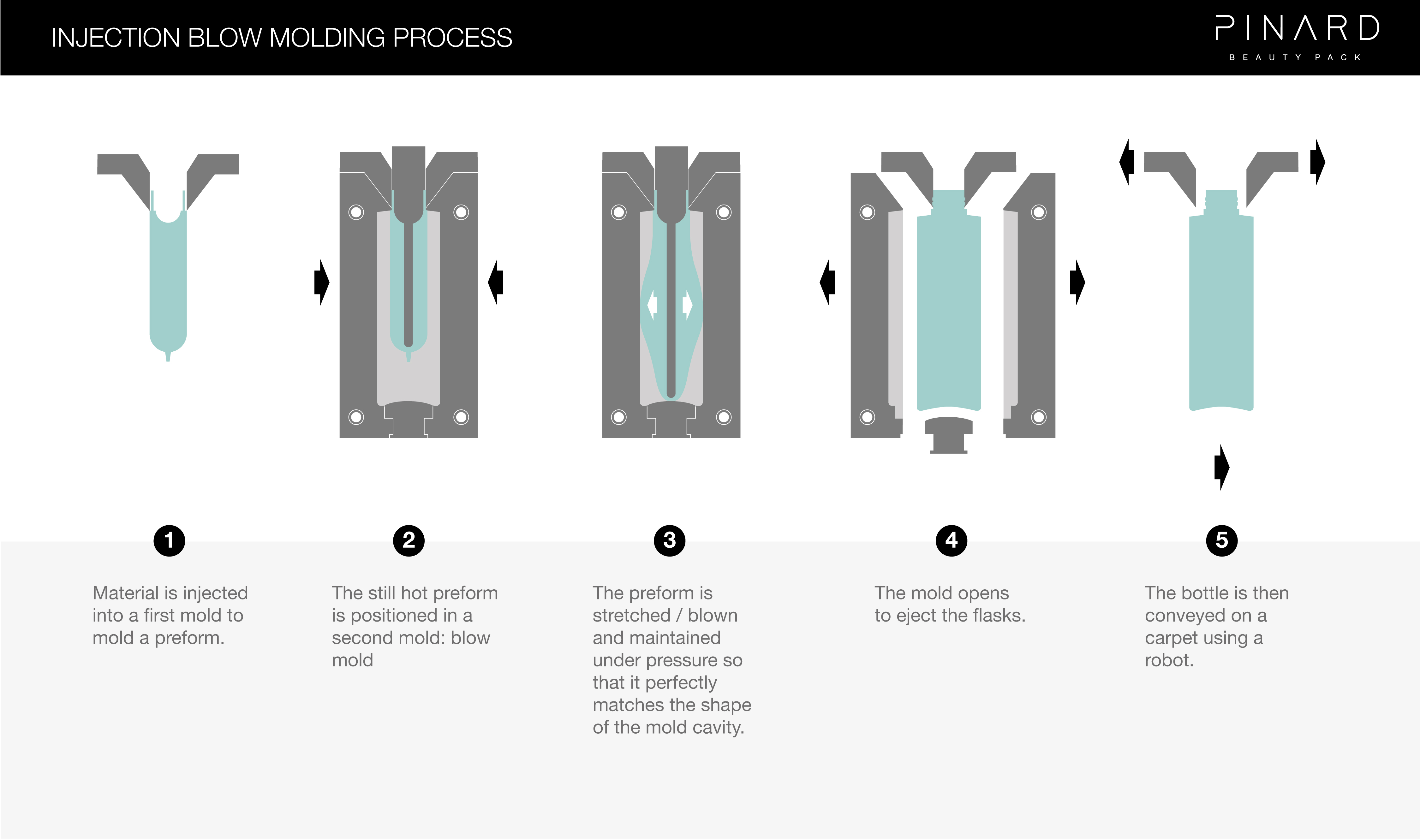

Injection blowing

This process consists of combining the injection technique with the blowing technique. Plastified material is injected under pressure into a mold to obtain a preform which is demolded while hot. It is then transferred to a blowing station to be stretched and blown into a finishing mold, in order to allow the preform to perfectly fit the shape of the mold.

In the 2 blow molding workshops:

19

Bi-oriented hot cycle machines

1 to 10 indentations

Decoration in Mold

A new innovative and more responsible technology for your decorations

This new innovative molding technology makes it possible to obtain personalized surface effects (matt frosted, engravings, etc.) without additional decoration/finishing steps.

This new process improves the Recyclability of the Packs, their Carbon footprint, while providing a real Technical-Economic solution

18

Decorating machines including:

6

screen printing machines 1-5 line colors

5

Semi-automatic screen printing machines

7

Hot stamping machines

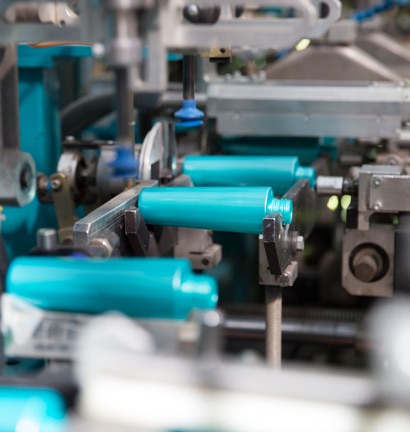

Decoration

18

Decorating machines including:

6

screen printing machines 1-5 line colors

5

Semi-automatic screen printing machines

7

Hot stamping machines

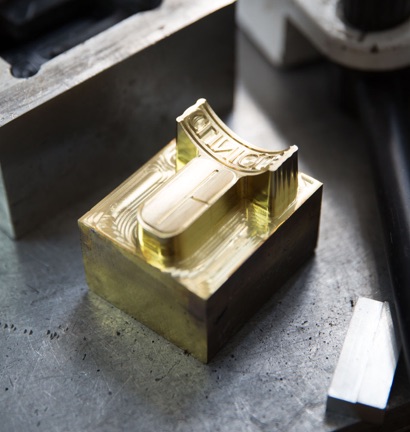

Hot stamping